The following case study is about the success long time Xenium Client, Poly-Cast, had with a summer intern from the Digital Design and Manufacturing Program at Sherwood High School.

Recruitment Challenge

In the summer of 2013, Poly-cast recognized the need to automate one of their manufacturing processes in order to improve efficiency. They had the expertise inside the business that was necessary to move forward with the project, but lacked the bandwidth. They saw this as an opportunity to bring in their first summer intern – a student with experience in mechanical design and the ability to drive the project from start to finish.

They worked closely with a recruiter to identify qualified candidates for the intern position. In the process, they met John Niebergall, the founder of the Digital Design and Manufacturing Program at Sherwood High School and were given the opportunity to see the students at work. Poly-Cast President, Dan Leedom, and Engineering and Tooling Manager, John Schwend, were shocked to see how advanced these young students were in Computer-Aided Design (CAD) and 3D printing. When Niebergall found out that Poly-Cast was in need of an intern, he referred Isaac Marshall, a first year engineering student at George Fox who had recently graduated from the program.

Through the interview process they found that compared to the other candidates, Isaac was highly qualified with the skills necessary to design and drive the project, which would later yield tremendous results for the company.

“Partnerships are a great avenue for setting up kids with careers. Industry doesn’t talk teacher talk, and teachers don’t talk industry talk. They are both very different systems but when we work together to help each other, it’s powerful.” – John Niebergall Sherwood High School

Utilizing Talent

John Schwend, Engineer and Tooling Manager at Poly-Cast, was the owner of the project and set the following goals to be achieved by Isaacs design:

- Reduce a 2 operator job to a 1 operator job

- Avoid a cost increase to the customer

- Improve process efficiency

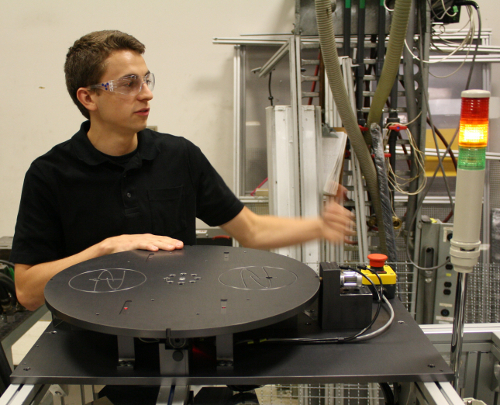

Isaac was provided with the resources he needed, including access to experts in the business and from there was able to put a design plan together. He organized meetings for his plan to be reviewed by the engineering and manufacturing production team and informed key stakeholders throughout the process, receiving buy-in the entire way. Once approved, he moved forward with the design to complete the project.

“He was set up with the right skills, obviously a bright young person. Giving him the right input and access to people with certain knowledge, he was able to use it to achieve the goals we were after.” – John Schwend Poly-Cast

Summer Intern Success

Isaac was able to achieve the initial goals that Poly-Cast had hoped for and exceeded expectations overall. Results were as follows:

- The process was reduced from a 2 operator job to a 1 operator job, which allowed those workers the time they needed to work on other projects.

- There was no cost increase for customers which allowed the price for parts to remain the same.

- Process efficiency improved by 15% so they were better able to keep up with increased customer demand.

- Set Poly-Cast on a path of integrating more automation with the blueprint, knowledge and ability to succeed.

Seeing the results achieved by a student coming out of a Science, Technology, Engineering and Mathematics (STEM) program such as the one at Sherwood High School is promising for the future of manufacturing. Not only does it prepare students for the workforce, but it is correcting the false perception of manufacturing as a dwindling field offering low-skilled jobs to a desirable lifelong career.

“When I see someone coming out of high school with this knowledge base, it gives me hope that America is moving in the right direction for developing a skilled work force to compete in the global economy.” – John Schwend Poly-Cast

About Poly-Cast, Inc.

Poly-Cast is a high quality custom plastic injection molding supplier for automotive, transportation, medical, instrumentation, industrial and consumer plastic products. They have been serving innovative markets since 1972 and strive to be a strategic asset to their clients, helping them to achieve their targeted market leadership positions.

They have been a client of Xenium since 2000, utilizing the PEO model for payroll, HR and benefit programs.

Sherwood Manufacturing Program

John Niebergall, the Engineering Instructor at Sherwood High School is setting students up for success with engaging, hands-on activities that prepare them for work in the manufacturing and engineering industry. While many schools made the decision to remove wood shop and home economics as elective options, Sherwood enhanced their traditional shop classes with 21st century technology. Students are able to bring their creations to life by prototyping with industry equipment including 3D printers and scanners, lasers and CNC equipment.

Many schools are following Sherwood’s example by reintroducing these programs and investing in industry equipment with the realization that these programs will contribute to the growth of the economy.

“The focus is on how we can get kids excited about the industry. I’ve always been a believer that if we don’t expose kids to these options, then they are never going to consider it.” – John Niebergall Sherwood High School